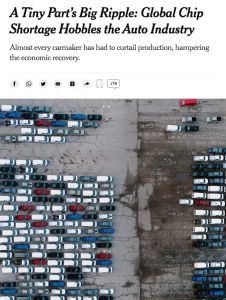

A Tiny Part’s Big Ripple: Global Chip Shortage Hobbles the Auto Industry

Almost every carmaker has had to curtail production, hampering the economic recovery.

Recommendation

Auto assembly plants are slowing, and dealerships are empty because semiconductors are in short supply – semiconductors run cars’ entertainment systems, fuel injection and cruise control. They are necessary in electric cars and autonomous vehicles. Due to the shortage, one GM plant closed. Others are reserving limited chip supplies for high-end brands. As Jack Ewing and Neal E. Boudette report in The New York Times, the chip shortage occurred as the economy revived, and people became eager to buy cars, but semiconductor manufacturers focused on the lucrative consumer electronics market, including smartphones.

Summary

About the Authors

Jack Ewing writes about business, banking, economics and monetary policy from Frankfurt. Neal Boudette is a US auto industry beat reporter at The New York Times.

Comment on this summary